About Us

We are the largest manufacturers and suppliers of Guar Gum powder and Guar Gum Splits in Gujarat, India. We here at Ashok Industries give great importance to Quality. Packaging of Guar Gum is done in such a way that it preserves the highly delicate product in good condition for a long time.

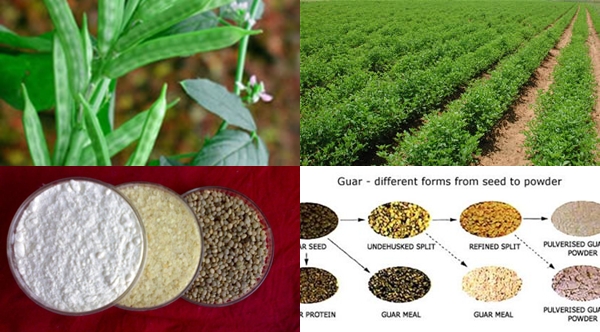

Ashok Industries is a Family managed firm in a business of acquiring processing and marketing Guar Gum for the last 31 years. Based in the region of Jodhpur in state of Rajasthan, India, the firm has a tradition of maintaining strong ties and business links with quality Guar Gum growers in India, which is the largest grower of Guar Gum crop all over the world. The processing plant itself (Jodhpur, Barmer and Sanchore) is located in a region which produces maximum guar gum crop. Ashok Industries therefore has the advantage of choosing the best raw material. The raw material is graded, processed and inspected by the Quality Assurance Team. It is then packed and distributed as per customers’ demand.

Business

Manufacturing & Quality

Ashok has made significant investments in sophisticated manufacturing technology. All the factories are equipped with modern automated machinery that helps maintain high quality levels as well as production volumes. Currently, the factories have a combined capacity to produce approximately 6,000 MT annually.

This includes:

• Raw material receipt and analysis from pre approved suppliers

• Regular analysis of in process samples

• Documentation of various in process parameters for repeatability and consistency in product

• Final blending and analysis before packing

• Separate areas for raw material storage, processing, packing and separate warehouse for finished goods stacking

• Pest Control Programmed inside and outside of the facility

• Transport qualification for finished goods transport